What is a Hazardous Area?

An area where gases, vapours, mists, or dusts in the atmosphere exist with the potential to combine in a way that can ignite under certain operating conditions.

Explosion Proof Lighting & Light Switches Explained

What is Explosion Proof/Hazardous Area Lighting?

Explosion proof and hazardous area lighting are durable lighting fixtures designed to contain sparks and flammable materials (gases, vapors, dust and high temperatures) which pose risks for fire and explosion. This type of lighting is used in various settings from worktops, laboratories, warehouses and even commercial kitchens.

How are Hazardous Areas Classified?

By the likelihood of flammable material(s) being present.

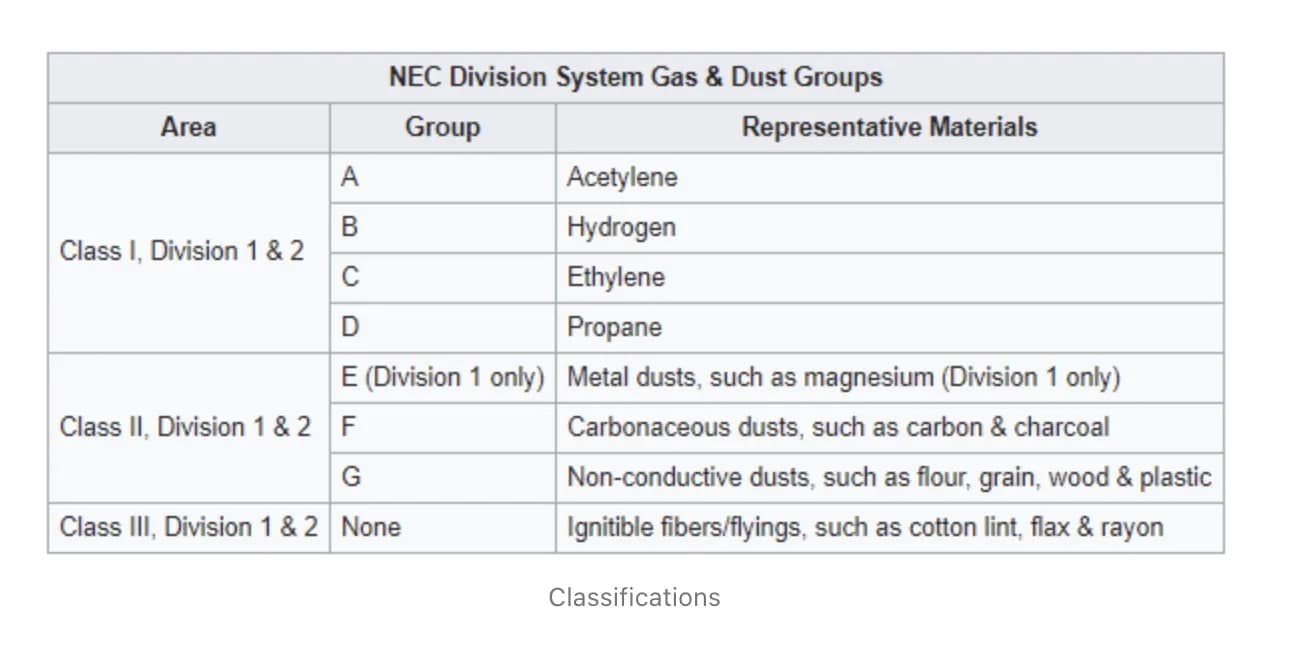

See Classifications :

Hazardous Area Classification System

(NEC article 500 through 503/CEC section 18)

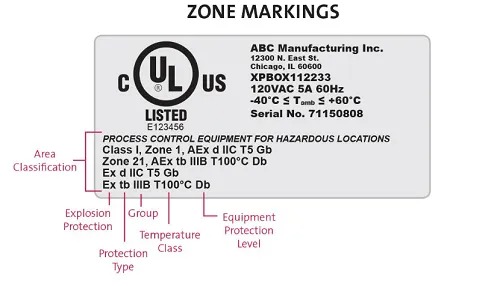

Sample Marking

Hazardous Locations are classified by the likelihood of an ignitable concentration of combustible material being present. There are two systems in place, including the traditional North American Division system as well as the alternative Zone system. See below for further details:

Division 1 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors can exist under normal operating conditions.

Division 2 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are not likely to exist under normal operating conditions.

It’s important to consider the above mentioned conditions when acquiring electrical equipment suitable for D1/D2 in Colorado.

Materials are divided by type:

Class I – Flammable gases, flammable liquid-produced vapors, and combustible liquid-produced vapors. This luminaire can be used as a spot light, down light, tunnel light, or strip light which can provide general illumination in hazardous locations, such as:

Examples Areas:

- Petroleum refineries, and gasoline storage and dispensing areas

- Dry cleaning plans where vapors from cleaning fluids can be present

- Spray finishing areas

- Aircraft hangars and fuel servicing areas

- Utility gas plants, and operations involving storage and handling of liquefied petroleum gas or natural gas

Class II – Combustible dusts that may combine continuously, periodically, or due to malfunction or failures.

Examples Areas:

- Grain elevators

- Flour and feed mills

- Plants that manufacture, use or store magnesium or aluminum powders

- Producers of plastics, medicines and fireworks

- Producers of starch or candies

Class III – Ignitable fibers/flyings. Typically these fibers and flyings are not suspended in the air, but can collect around machinery or on lighting fixtures and where heat, a spark or hot metal can ignite them.

Examples Areas:

- Textile mills, cotton gins. Cotton seed mills, flax processing plants

- Plants that shape, pulverize or cut wood and create sawdust or flyings

Materials are further divided into Groups for Class I, Divisions 1 and 2:

A – Acetylene

B – Hydrogen

C – Ethylene

D – Propane

Materials are further divided into Groups for Class II, Division 1 and 2:

E – Metal Dusts (Div. 1 only)

F – Carbonaceous Dusts

G – Non-Conductive Dusts (flour, grain, wood, plastic, etc.)

There are no groups for Class 3.

Which Type Of Lighting Is Right For Me ?

- Class 1, Division 1

- Class 1, Division 2

- Class 2, Division 1

- Class 2, Division 2

- Class 3, Division 1

- Class 3, Division 2

Consider C1,D1 if…

The lighting of category C1D1 in Colorado is used when Ignitable concentrations of flammable gases, vapors, or liquids:

- can exist under normal operating conditions;

- may exist frequently because of repair or maintenance operations or leakage; or

- may exist because of equipment breakdown that simultaneously causes the equipment to become a source of release.

LED class 1 div 1 lighting in CO is used in hazardous areas to prevent high voltage, high current equipment from generating an ignition source. Heavy-duty luminaires surround the parts that produce sparks, so if steam or gas leaks and is ignited, it contains an explosion.

Suitable for general industrial and general marine applications requiring anti-steam or waterproof fixtures.

Consider C1, D2 if any one of these is true…

- Volatile flammable liquids or flammable gases or vapors exist, but are normally confined within closed containers and can only escape if they are damaged, broken, or due to a malfunction.

- Class 1 div 2 light fixture in CO for areas where active mechanical ventilation prevents gases or vapors of combustible concentrations and may become dangerous due to malfunction or abnormal operation of the ventilation equipment.

- The area is adjacent to Class 1 Zone 1, occasionally the concentration of flammable gases or vapors may be transmitted unless adequate positive pressure ventilation is provided through a clean air source to prevent such communications and to effectively prevent ventilation failure.

Consider C2, D1 if

- If Ignitable concentrations of combustible dust can exist in the air under normal operating conditions;

- If Ignitable concentrations of combustible dust may exist because of equipment breakdown that simultaneously causes the equipment to become a source of ignition; or

- If electrically conductive combustible dusts may be present in hazardous quantities.

Consider C2, D2 if…

- If combustible dust is not normally in the air in ignitable concentrations;

- If dust accumulations are normally insufficient to interfere with normal operation of electrical equipment;

- If dust may be in suspension in the air as the result of infrequent malfunction of equipment; or

- If dust accumulation may be sufficient to interfere with safe dissipation of heat or maybe ignitable by abnormal operation. The lighting of category C2D2 in Colorado should be used in such situations.

Consider C3, D1 if…

- The area is a location in which easily ignitable fibers or materials producing combustible flyings are handled, manufactured or used.

Consider C3, D2 if…

- The area is a location in which easily ignitable fibers are stored or handled other than in the process of manufacture.

Atex/Zone Classification

(NEC article 505-506/CEC seciton 18)

Sample Marking

Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are present continuously or for long periods of time under normal operating conditions.

Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are likely to exist under normal operating conditions.

Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are not likely to exist under normal operating conditions.

Ignitable concentrations of combustible dust or ignitable fibers/flyings are present continuously or for long periods of time under normal operating conditions.

Ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist occasionally under normal operating conditions.

Ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to occur under normal operating conditions.

Additional Resources

Use the additional resources and links below to learn more about this topic:

Zone Classification

Durable lighting fixtures designed to prevent and avoid potential explosions. The parts of the light fixtures are not likely to explode.

Explosion proof lighting can be used in places like commercial kitchens and industrial settings to avoid accidents caused by lights shattering.

Lighting designed to minimize the risk of flammable gasses, vapors, or dust being present in the area.

Hazardous location lighting can be used in places like marinas, oil refineries, and processing plants where gasses, vapors, and dust are likely to exist.

Installation of both explosion proof lighting fixtures and hazardous location lighting may be necessary depending on the location and legal guidelines

By the likelihood of flammable material(s) being present.

Contact Us

Let’s find a solution that works best for your organization. Fill out the form, or give us a call to talk to an expert today.

- infoepicstarex.com

- 720-244-2001

- 2851 South Parker Road Aurora, CO 80014

- Mon – Fri 8:00am – 5:00pm